2 -Trailer Axle Spindle Seal Repair Sleeve Kit Upgrade 3500# Axle #2 Spindo

Part Number - 05613U

2 (TWO) - 2.56" Seal Spindle Seal Axle Repair Kit #2

Fits many 3500# Spindles (Dexter ALKO AXIS)

This will cover the worn or damaged seal area on standard 3500# Trailer axles (1.68 & 1.719 seal ID Size)

This fits axles that use the L68149 inner bearings (1.37" ID)

Basically repairing (covering up) a damaged Axle seal area.

The repair sleeve does NOT fit tight, having an ID of 1.875, it will cover severely damaged spindles.

Includes 2 new seals, and 2 new repair Sleeves

This Sleeve will repair Damaged seal area on common 3500# Trailer axles (Dexter, ALKO and others) 1.719" x2.56" Seal size

Read THIS:

This kit works with all Common 3500# axles from Dexter, ALKO, and others.

These axles have a 1.375" ID inner bearing, and 1.719" ID grease seal.

The repair sleeve in this kit is 1.819"ID, so it will easily go over the damage seal area.

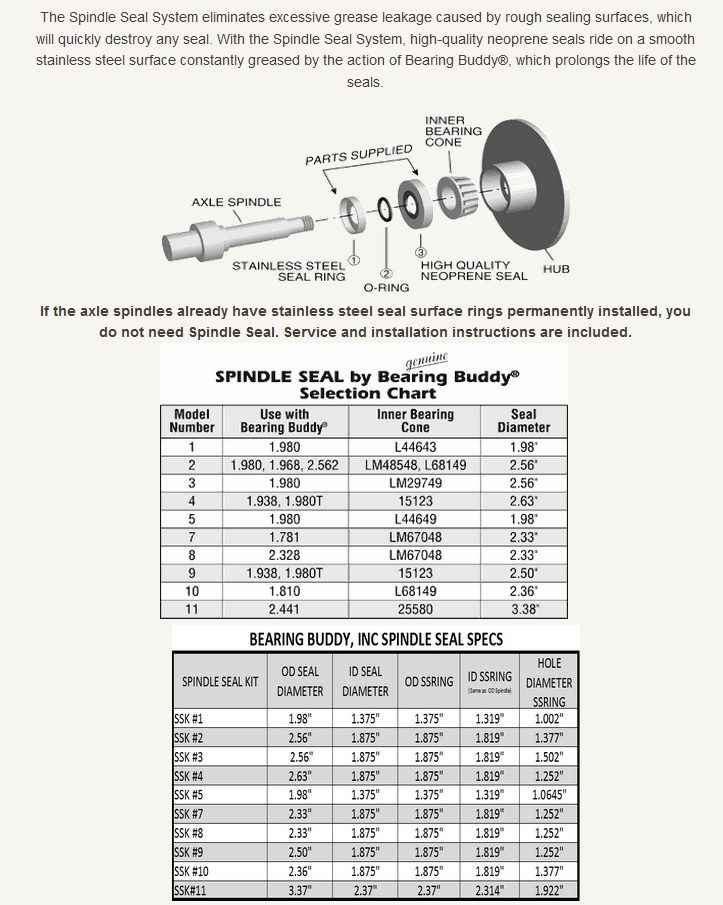

Kit number 2 below:

Seal Outside Diameter: 2.56"

Will NOT Work on UFP axles (Square tube, usually used on boat trailers) with the 1.68" ID Grease seal

(So, if you have a boat trailer with a square tube axle, this may not work for you)

Installation Instructions

1. Lay the trailer hub on a flat surface with the inside bearing side facing upward.

2. Align the neoprene seal with the bearing hole and hammer gently with a piece of wood to push the neoprene seal into the hub.

3. Place the stainless steel ring on the spindle. Place the o-ring on the spindle in front of the stainless steel ring as shown in diagram.

4. With Spindle Seal installed, make sure spindle nut is properly tightened. If nut (and hub) is loose, Spindle Seal wont function properly. If excessive grease leakage continues after properly tightening spindle nut, check components for wear or damage. If the problem still cant be located, contact the factory.

5. Kits 1 and 5 come with a wire ring inside the stainless steel ring that provides extra support to the ring. In some cases, it may be difficult to insert the cotter pin after these kits have been installed. If the hub moves outward on the spindle such that a cotter pin cannot be inserted through the spindles castellated nut, either (1) shorten the length of the nut (2) file a deeper groove on the nut or (3) purchase a thinner cotter pin.

FREE SHIPPING